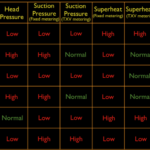

I went on a “commercial” service call this past Saturday to check two of four systems servicing a church nave. There had been a previous service company who had made some diagnostics and offered some corrective options. I started one of the two to make some sort of analysis and observed the suction line frosting early on at the condenser, accompanied by a low suction pressure reading. OK, some kind of airflow problem somewhere.

All four air handlers are ducted vertically, then do a 90˚ into a wall. Once passing through the wall, the connecting ductwork is concealed above a drop ceiling. The ceiling is very high, maybe 20′.

Air flow issues I typically see are dirty coils or filters, with only an occasional duct problem. I eliminated those possibilities within a few minutes, which left some sort of restriction, somewhere in the supply ducting. I drilled a small hole in the supply plenum, checked the static pressure and read 1.5 inWC which is way high for 5 ton air handlers. The pressure in one of the working units was only 0.2 inWC. At that point, I was at a loss for ideas on where to check for obstructions in the supply side since there’s no good way to access ductwork 20′ off the floor.

To further complicate matters, I checked the other unit which is next to the first unit that was on the list to check and it had the same blocked airflow issue, which got me to thinking in terms of the two systems discharging into a common plenum that was blocked, which goes against logical duct system design.

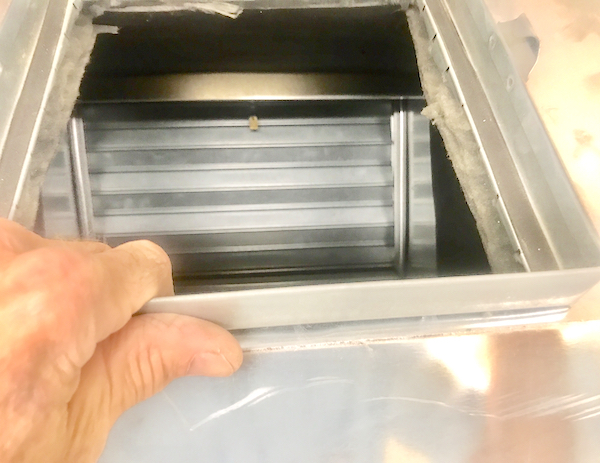

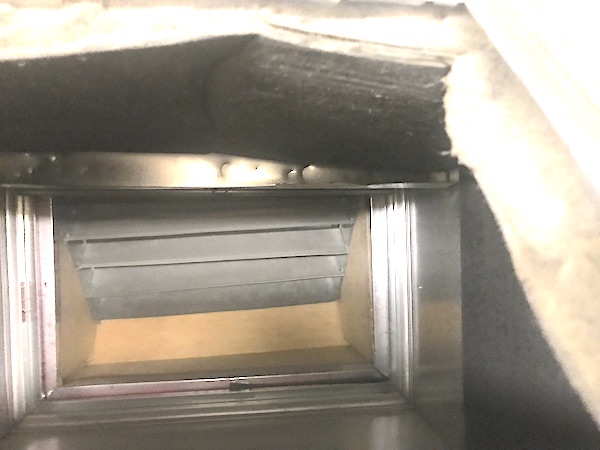

I had some conversation with the church representative about what I was thinking necessary for finding the problem and left for the day. Later on I was relating the issue I’d found with another HVAC buddy who mentioned the fire dampers might be closed…that thought had never crossed my mind. I wasn’t thinking about the church being coded for fire dampers but it all made more sense than my theories about duct restrictions. So I returned the following day with a sufficiently long ladder, set it up and climbed to the inspection port at the top if the vertical plenum…there it was, closed static folding damper.

They normally look like this when not closed. They are held in the open position by thermal link that melts at high temperature. What you see behind the damper are turning vanes.

Had a smooth experience with 6666betlogin. The login process was easy, and I didn’t encounter any issues. Fast login process. I´m pretty happy. More Information in: 6666betlogin

Been playing around on jilislotgame. Honestly, it’s a fun way to kill time. Graphics are decent, and there’s a good variety of slots. Could be my new go-to! Give it a try: jilislotgame